LSCM Showcase

Automated Concrete Cube Testing System

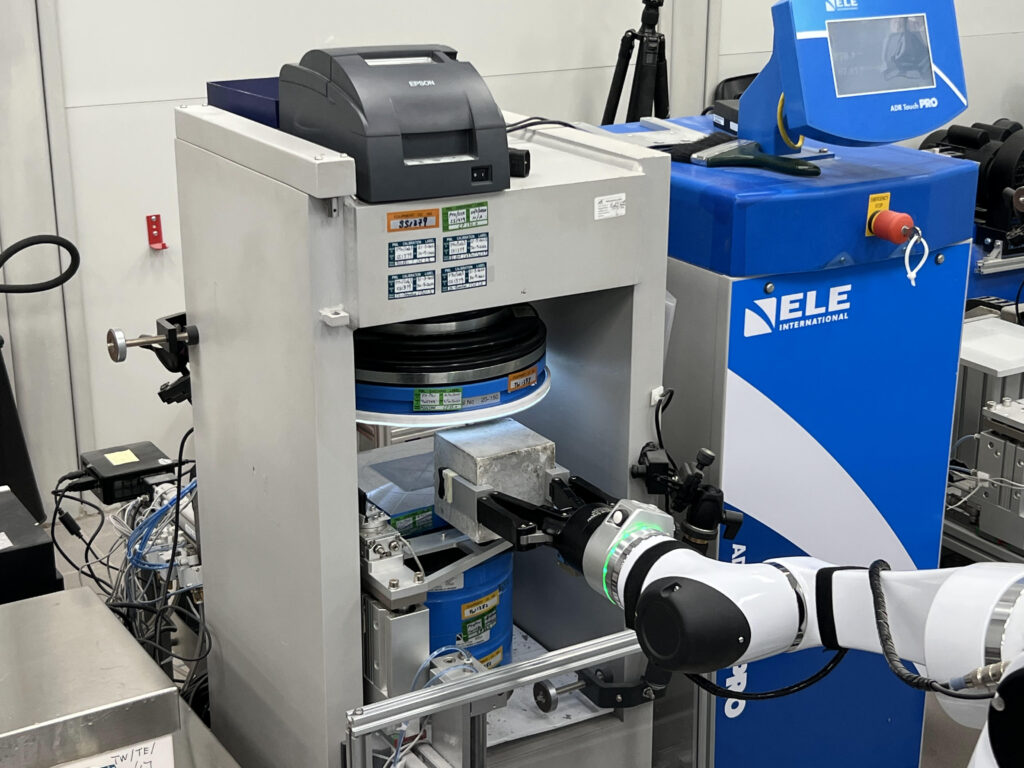

LSCM and the Geotechnical Engineering Office of Civil Engineering and Development Department (GEO/CEDD) jointly developed the Automated Concrete Cube Testing System. The system can automatically carry out the entire concrete cube testing procedure, including concrete cube curing, weight and dimension measurement and compression test. The system consists of an overhead xyz moving stage, robotic arm on rail, laser 3-dimensions measurement device and compression test machine. Equipped with Al technology, the system can distinguish whether the fracture mode of the concrete cube sample meets the prescribed requirements using computer vision technology. The system has already been put into operation at GEO’s Public Works Regional Laboratory (Sham Shui Kok).

RFID Device (Two-piece Device for Tolling Application)

The system consists of the integrated antenna and a 2-piece device which includes the RFID card (driver’s card) and the slot. The integrated antenna is a UHF RFID antenna that LSCM specially designed for installation in the lamp pole. Considering the deployment in outdoor environment, the antenna is a thin structure, and it is lightweight, wind resistant and UV/IR resistant.

While TOPPAN Edge (Hong Kong) Ltd. utilised a groundbreaking combination of PCH, PETG, and stainless iron plates materials in the production of the RFID card (driver’s card) and the slot. The RFID card can store the unique identity of the driver’s tolling account. It has a short-read range of around 3cm. Once the card is put into the slot, the antenna in the slot will couple with the RFID card to extend the read range to more than 6m.

Besides, 2-piece tag device has a magnetic-locking feature, which facilitates the application in tolling systems. LSCM collaborated with TOPPAN to ensure 100% pass rate through specialised QC tools for each card and RFID slot. For commercial vehicles with multiple drivers driving the same vehicle, the 2-piece tag device could easily differentiate different drivers, and the RFID card can serve as the driver's identity card. In the tolling application, both the driver’s and vehicle’s information can be collected at the same time in each transit.

e-Smart Port Platform

LSCM and the Transport and Logistics Bureau signed an MoU to study the development of the e-Smart Port Platform (eSPP). It is a data-smart infrastructure and an inter-organisational software platform to facilitate the sharing of port and logistics information in the port community. eSPP deploys blockchain technology, smart contracts, advanced IoT and global positioning technology, etc. to track and visualise the global supply chain and port logistics effectively. eSPP also includes a News Portal App which gathers industry news, reports, blogs, and other useful information for the port community’s reference and discussion.

Smart Area-Wide Traffic Control System for Better Mobility

A Smart Area-Wide Traffic Control System is developed by deploying cameras, sensors, and algorithms to adjust traffic signal timings based on real-time traffic conditions. With the smart system in use, significant reductions in delays and queue lengths are achieved in an area with multiple junctions as compared to the traditional traffic control system.

Intelligent Traffic Enforcement System

An intelligent Traffic Enforcement System is developed to identify and record roadside traffic offences such as illegal stopping at a road section with no-stopping restriction. The system is helpful in reducing congestions and enhancing road safety.

Electronic Power Assist Trolley System

This is an electronic power assist trolley system with an intuitive control function. Sensors are strategically embedded in the trolley handlebar to measure the micro deformation of the materials when force is applied by the user. The torque vector is calculated 100 times per second based on the sensor's value by an onboard AI controller. Amplified torque is generated by two motors connected to the wheels of the trolley. Turning left/right or forward/backward depends on the calculated torque vector. The manoeuvre of this power assist trolley is the same as a traditional mechanical trolley without buttons, joysticks and controllers. No prior training is required when using the trolley and it can be manoeuvred like an empty trolley even if it is heavily-loaded. The built-in power regeneration and brake system make it safe for use even on a ramp.